New design customized metal seamless rain gutter cold roll forming machine

Product Description

1. Material: 1) Suitable Coil Thickness: 1mm 2) Suitable Raw Material: Galvanized steel sheet 2. The equipment including Roll forming machine 1 set Electrical control system 1 set Hydraulic system 1 set Hydraulic de-coiler 1 set Max. loading 3-5 T

Manual decoiler Single - head de-coiler, unilateral discharge Using electric pressure internal intensify Max. loading weight : 3-5tons Main roll forming machine Main engine power: 15KW Structure: Welded plate Drive: Gearbox driving Spindle diameter: Φ80mm, Material : Gcr12 quenching and tempering treatment Roller material: GCR12 Quenching to 58°-62°, Surface plating treatment Stations: About 5-10 stations The unit adopts frequency conversion 8m-15m/min (excluding punching time) Computer PLC control, operation panel with touch screen display

Specifications

| Model |

GWC127 |

Note |

| Material spec |

Color plate, galvalume plate, aluminum plate and cooper plate |

This machine is customizable upon each customer's requirements and the characteristics of processed material. |

| Feeding width |

310mm |

| Processing thickness |

0.3-0.8mm |

| Roller material |

45# steel coated with hard chrome |

| Main motor power / hydraulic station power |

7.5kW / 5.5kW |

These parameters can be set according to the required production capacity. |

| Forming passes |

16 |

| Forming speed |

5-15 meters/minute |

| Machine dimensions |

11×1.0×1.0m |

| Machine weight |

8T |

Features of this Galvanized Drywall Used Omega Profile Light Gauge Steel Framing Cold Roll Forming Machine

- lower cost

- high efficiency

- reliable working

- low energy consumption

Components of the Galvanized Drywall Used Omega Profile Light Gauge Steel Framing Cold Roll Forming Machine

1. Steel strip supporting frame

2. Feeding platform

3. Automatic shearing system

4. Hydraulic system

5. Steel strip unfolding system

6. Computer control system (imported computer)

7. High-precision automatic counter

8. Receiving table

Optional components of the Galvanized Drywall Used Omega Profile Light Gauge Steel Framing Cold Roll Forming Machine

Manual uncoiler frame in different tons

Hydraulic automatic uncoiler

Working space and workman for the Galvanized Drywall Used Omega Profile Light Gauge Steel Framing Cold Roll Forming Machine :

1. Ground-level land

2. ≥5T overhead travelling crane

3. Space for storing the material

4. Space for laying the machine

5. Road for vehicle moving

6. Workman: 2, operator and porter

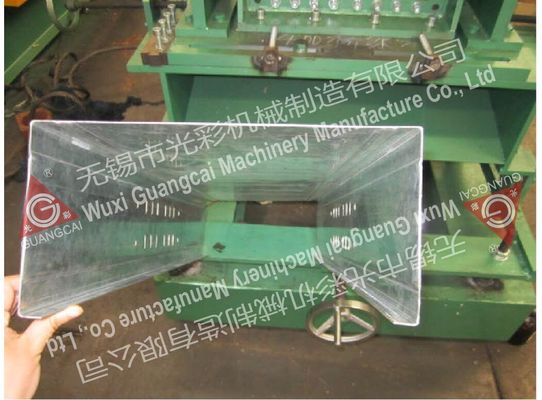

Rain Gutter Roll Forming Machine

The rain gutter roll forming machine can be designed according to the drawings and requirements provided by our client. It is used to fabricate rain gutters that could work together with down pipes to form the drainage system for the building.

Processing Flow

Passive decoiling →guided material feeding → roll forming → cut-to-length → offloading

Payment terms and after-sale service: 1) FOB Tianjin 2) Payment: 30% T/T deposit, and pay the balance before shipping. 3) Delivery time: 50 working days. 4) Guarantee period: 12 months limited warranty starting from date of delivery. Shipping cost for parts to be replaced during warranty period have to be borne by the customer. 5) Spare parts: bearings, buttons, chains, magnetic valve, protective tube etc. 6) Installation and training: 1. If buyers visit our factory and check the machine, we will teach you how to install and us the machine, and also train your workers/technician face to face. 2. Without visiting, we will send you user manual or video to teach you to install and operate. 3. COST OF INSTALLATION: The buyer should pay the installation charges (USD 100 one man one day). To the seller's appointed account by T/T before the seller's technicians go to the buyer's factory. The buyer pays the seller's technicians travel cost outside China, including round air tickets fee, accommodation and food, provide transportation from living hotel to the work place, necessary communication, and insurance, etc.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!